We use cookies to enhance your experience. By continuing to browse this site you agree to our use of cookies. More info.

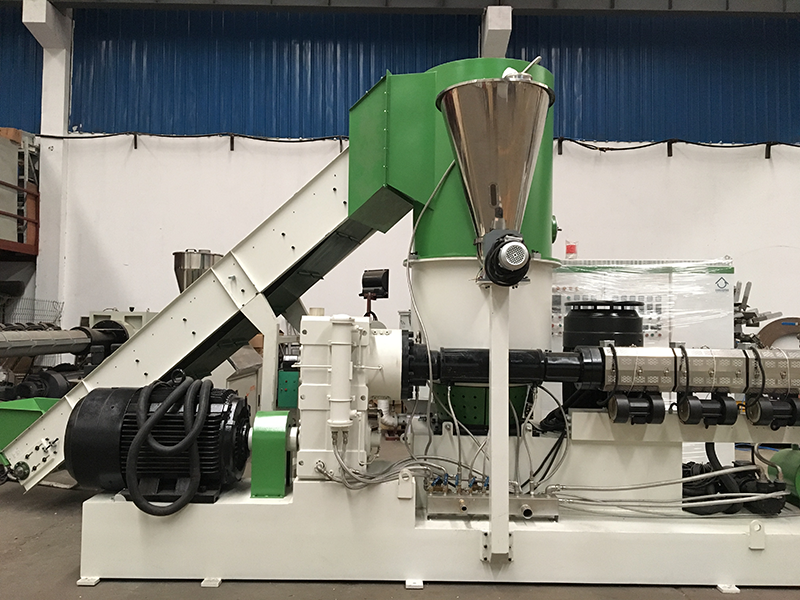

In this interview, AZoM talks to Annika Völp, process application specialist at Thermo Fisher Scientific, about twin-screw extrusion in battery manufacturing and research. Völp delves into the applications of these extruders on an industrial scale. Twin Extruder Machine

My name is Annika Völp. I am a process application specialist for extrusion at Thermo Fisher Scientific. In principle, extrusion is the process of pushing material through a die to give it a certain cross-sectional shape. This can be realized either by a piston or a screw extruder.

Image Credit: Thermo Fisher Scientific

The screw extruder is a device consisting of one or more Archimedes’ screws that rotate in a cylindrical barrel. Material is continuously fed into the barrel and sheared between the screw and bearing wall.

The material is melted by heat input in the case of hot melt extrusion or dispersed with solvents in the case of a wet extrusion. Eventually, the fluid material is compressed and pushed through a die to form the extradite.

The temperatures of the various barrel zones in the die are controlled by the operator as well as the screw speed and the feed rate of the material. The melt temperature and the melt pressure can be measured along the extruder barrel and in the die.

The torque is measured at the drive shaft of the screw. These parameters cannot be controlled directly but depend on the set temperatures, screw speed, and material throughput.

Image Credit: Thermo Fisher Scientific

Twin-screw extruders are extruders with two intermeshing screws, or even extruders with multiple screws have been developed. Unlike the single-screw extruder, twin-screw extruders can compound material fed into the barrel in addition to plasticizing and compressing it.

Twin-screw extruders are available with parallel screw designs or conical screws that can either co-rotate or counter-rotate. While counter-rotating conical twin screws can build up higher material pressure and resist higher torque, the co-rotating parallel twin-screw extruder exhibits the best compounding performance.

The screw design of parallel twin-screw extruders determines the material processing units. Powders, or pellets, are fed into the main feed onto elements with a wide screw gap. This zone is cooled so that the powder does not melt and block the port. In the next barrel zones, the temperature profile is set to melt the material and control its viscosity.

After, there is a zone with conveying elements, and it is optional for liquids to be fed into this zone. The first kneading zone plasticizes the material by shearing. A second conveying zone allows for secondary powder feeding.

The next compounding zone mixes all materials. In the third conveying zone, gases could be removed by venting the barrel. Finally, the pressure is built up and the material is pushed through the die.

Image Credit: Thermo Fisher Scientific

The screw design is specific to the material and the unit operations that the material is supposed to undergo.

Granulation can also be realized with an extruder. Granulation is the process that converts fine materials like powders or dust to larger particles called granules. As part of the post-processing, the granules can be compacted to form sheets, tablets, or pellets, which is easier after granulation.

Image Credit: Thermo Fisher Scientific

Granulation decreases the specific surface area, increases the bulk density, improves the flowability, prevents segregation, reduces dust formation, and eases compaction.

Granulates can be produced using a twin-screw extruder with an open discharge, meaning a die is unnecessary. The difference between dry or heat-activated granulation can be determined using a thermoplastic binder that connects the solid particles and wet granulation using a liquid binder.

Image Credit: Thermo Fisher Scientific

Twin-screw granulation can also be used to compound materials. The main difference to extrusion is that the material is not in a fluid state nor pressed into a specific shape.

Lithium-ion batteries represent state-of-the-art portable energy storage. Among other battery chemistries, such as lead-acid and alkaline, Li-ion batteries contribute 37% to the revenue share.

Li-ion batteries often contain an aluminum current collector foil coated with a cathode active material (CAD) such as nickel, cobalt, manganese, lithium-ion phosphate, or lithium nickel cobalt aluminum oxide, an anode made of copper collector foil coated with graphite, and a porous separator foil made of PE or PP, which is only permeable for lithium ions, not for its electrons.

Image Credit: Thermo Fisher Scientific

These layers of cathode, separator, and anode are soaked in an electrolyte that enables lithium-ion transport. All layers are either stapled or wound up to form battery cells.

The manufacturing process of lithium-ion batteries involves many steps, including the metal oxides and the graphite being mined and refined, as well as the mixing of anodes and cathode slurries from the material. The slurries are each coated onto the current collector foil to form the electrodes.

Separators are purchased from one of the few market-leading suppliers, stacked with the electrodes, and further processed into battery cells.

Finally, the cells are assembled into a battery, which is then pre-conditioned for several days by charge/discharge cycles called formation and aging.

Extruders can be used for compounding granulation of graphite with other inert materials. A twin-screw extruder with open discharge can be used for granulating carbon black powder, which also becomes less dusty and free-flowing. The compounding granulation can also be applied to compound solvent-free electro paste.

Image Credit: Thermo Fisher Scientific

Separator foils are produced by extrusion. The process is already fully developed, but lab-scale twin-screw extruders can be useful in this process, helping in the development of novel battery concepts such as solid-state batteries, gel polymer separators, or solid electrolytes.

Image Credit: Thermo Fisher Scientific

In electrode manufacturing, twin-screw extruders can also be used for continuous cathode or anode slurry mixing. Although planetary mixes are conventionally used in batch mode for mixing the electro paste, twin-screw compounding presents an advantageous alternative technology.

Image Credit: Thermo Fisher Scientific

The core process in lithium-ion battery manufacturing is the manufacturing of the anode and the cathode. The mixing of the active material with solvents, binders, and additives is conventionally done in planetary mixers and typically takes four to eight hours.

Subsequently, the slurries are stored in steel buffer tanks to prevent phase separation, and these feed a slot-die coater that applies the slurries onto the current collector foils.

The slot-die coating requires low viscous slurries with a high solvent content of 45%. The solvent for cathodes usually used is N-Methyl-2-pyrrolidone (NMP), which is toxic, expensive, and needs to be removed and recycled after coating. The coating is followed directly by a drying line to evaporate the solvents.

Image Credit: Thermo Fisher Scientific

Subsequently, the coated foils are calendared in a roller press. Slitting the electrodes into shape is done either mechanically or with a laser foil slitter and optionally followed by another drying step.

Solvent evaporation and recycling is the major energy consumer, with 20% of the total energy required for cathode manufacturing. Continuous twin-screw compounding can be applied as an alternative for batch-wise mixing of the electrode slurries.

Every continuous process has the advantage of increased reproducibility over batch-wise production, i.e., you have no batch-to-batch variations because there are no batches. Once the extruder is running, it continuously produces slurry with no variations.

There is also less need for operator interference, so there is a lower chance of variability as a result of different operators.

Additionally, the dispersion quality is improved by twin-screw mixing because the shear forces acting on the material is higher than in planetary mixes. The narrower particle size distribution leads to less blockage of the downstream screen filter. Far fewer screen changes are required than for planetary mixing.

Image Credit: Thermo Fisher Scientific

The residence time of the material in the extruder is in the order of minutes instead of hours as in the planetary mixers, and therefore the slurries catch fewer impurities. Extruder manufacturers claim that the impurities caused by the extruder for cathode slurry production can be reduced to 0.5 ppm with the appropriate screw and barrel material.

Twin-screw compounders also save space, and little labor is required once it is up and running. The continuous production requires no downtime for opening and withdrawing the slurry, and, therefore, less cleaning work is also required.

Continuous processing is also faster and more material effective as material loss is minimized. While a conventional batch of slurry takes four to eight hours to be mixed with a planetary mixer, a twin-screw extruder only takes a matter of minutes.

In batch mode, planetary mixers lose material after every mixing because some material remains on the contact parts. However, the twin-screw extruder is self-wiping, so only a minimal amount of material has been found to remain in the extruder. This means that the device does not need to be stopped and cleaned as frequently as the batch mixer. However, the loss of material in the startup of the extrusion process also needs to be considered.

Another important advantage of twin-screw mixing is that the shear forces acting onto the material are adjustable and normally much higher in a twin-screw extruder than in a planetary mixer. This allows it to mix thoroughly even with less solvent addition.

The Process 11 Twin-Screw Extruder can be used for cathode slurry compounding. The lab-scale extruder with an 11 mm screw diameter is small enough to be placed onto a safety work bench. A gravimetric powder feeder is used to control the cathode material throughput.

The solvent is dosed into the extruder with a peristaltic liquid pump. The mixed slurry is collected at the extruder outlet. The particle size distribution in the slurry can be quickly checked with a Hegman grindometer. The slurry is wiped across tile cavities and reveals a size distribution between 15 and 70.5 µm.

Image Credit: Thermo Fisher Scientific

Formulations with binders that form fibroids under shear to form a network between the cathode active material particles are currently subject to proving. This allows calendaring a dry cathode to granulate directly onto a current collector foil and to save a lot of energy conventionally consumed for the drying step.

Sheet extrusion of the electrode material is also possible. The sheet can be guided directly into the roller press and provides a uniform dosage.

The application of extrusion in electrode manufacturing can reduce solvent consumption in electrode pasting and mixing and thereby reduce energy consumption and costs. It also saves space because the large drying line becomes obsolete.

In a dry granulation with a polymeric binder, the extruder is equipped with an open discharge that ejects the soft-form granules without compaction. Cathode materials are fed into the twin-screw extruder, and the binding component is dispersed and sheared to form a network between the cathode active material.

Image Credit: Thermo Fisher Scientific

Free-standing electrodes can be extruded by dosing the cathode materials and small amounts of solvents separately into the twin-screw extruder. The mixed paste is extruded through a sheet die, and in this setup, the free-standing electrode is pulled and compacted with a sheet takeoff. Likewise, it could be directly guided into a calendar.

Image Credit: Thermo Fisher Scientific

The processing steps for the lab-scale production of cells are just as you would expect for such large-scale production but with downsized equipment. The dry electrode material is mixed in a 3D shaker mixer. Subsequently, the dry matter is dispersed into a solvent with a dissolver or in a tabletop planetary centrifugal mixer.

The slurries are then coated onto the collector foil with a doctor blade or a slot-die coater and compacted in a roller press or manual press. Electrodes are cut out with a puncher, stapled, vacuum sealed, and filled with electrolytes. The performance of the cells is then tested in a cycler.

Again, the mixing step can also be done with a twin-screw extruder, but on an appropriate scale because novel material is usually available in small quantities, such as 100 g.

The extrusion process is scalable, given the geometrical ratios of screws and barrel are kept constant. The high surface-to-volume ratio of extruder barrels provides better scalability in terms of heat transfer via the walls than steel containers. This ensures that a novel process developed on a lab-scale extruder can be later transferred into production.

Image Credit: Thermo Fisher Scientific

Second, a segmented screw design and many feeding parts of lab-scale parallel twin-screw extruders renders them ideal for research and development. The screw configuration can be adjusted to optimize the shear history of the material within minutes.

Image Credit: Thermo Fisher Scientific

The flexibility in dosing positions allows for the residence time in the extruder to be adjusted for the individual ingredients. With dissolvers and centrifugal mixers, only rotational speed and residence time can be varied.

Third, the split barrel design of a lab-scale twin-screw extruder allows for much faster cleaning. This is very valuable for research for switching quickly between different materials. Additionally, it allows for observation of the material along the screws after an abrupt stop of the extrusion process. This provides information for adjustment on the screw configuration to optimize the mixing process.

Image Credit: Thermo Fisher Scientific

Lab-scale extruders with exchangeable barrels are also available. This allows the use of several barrels dedicated to a particular material to avoid cross-contamination. For example, one barrel is used for cathode mixing and another one for the anode.

Commonly, the battery material is sensitive to humidity, and solid-state battery material is sensitive to nitrogen. This means that operators need to work in a dry or even inert atmosphere and later in a glove box.

Image Credit: Thermo Fisher Scientific

It is not necessary to work in a glove box with an inert gas atmosphere. It might be necessary to place the equipment in a safety cabinet to spare the operator from contact with toxic solvents and powders.

The manufacturing environment of battery cells underlies high requirements to ensure the cell’s performance as well as safety. It must be particle free and dry with a dewpoint below minus 60 °C. Lithium salt reacts to lithium hydroxide upon contact with humidity.

If pure lithium anodes are handled or solid-state batteries are produced, the environment needs to also be free of oxygen and nitrogen as both react with pure lithium in a strongly exothermic reaction, and some sulfide solid electrolytes form toxic H2S.

Processing of these materials can only be realized in an inert gas atmosphere, for example, under argon in a glove box. The advantage of a glove box is that it enables lithium-ion battery research on a small scale without the need for an expensive dry room.

Image Credit: Thermo Fisher Scientific

In contrast to the operation of an extruder in a dry room, the lab environment stays free of dust and solvents when the extruder is open for cleaning inside a glove box. This makes the extruder operation safer when handling hazardous substances. The conditions inside the glove box are also more stable and undisturbed by the presence of humans in the room.

Thermo Fisher Scientific provides lab-scale extruders together with a glove box tailored to the dimensions and the handling of the extruder. The glove box is operated with argon and is equipped with a nitrogen purification and a solvent filter to provide an atmosphere with less than 1 ppm of nitrogen, oxygen, and water.

Video Credit: Thermo Fisher Scientific – Materials & Structural Analysis

It also has an extruder control panel outside the glove box, a vacuum cleaner, an argon piston, and an endless liner to ease the operation.

In addition to the Thermo Scientific Process 11 tabletop extruder, there are also larger twin-screw extruders with 16 mm and 24 mm screw diameters available. This portfolio covers a material throughput range from below 100 g per hour to up to 50 kg per hour.

Unlike production-scale extruders, the extruders are easily operated by just one person, require very small sample volumes, and are scalable to larger sizes. These features save time and money on application testing, enable the development of products and test materials at a small scale, and provide process experience and training of operators for larger-scale machines.

I want to recall the advantages of twin-screw extruders applied for continuous electrode paste mixing as they reduce quality fluctuations in the slurries, reduce material loss, and production downtime. They have a smaller footprint, and the operation is less labor-intensive than for batch mixers.

Additionally, solvent consumption can be reduced with an extruder while still increasing the dispersion quality and the mixing speed.

Extruders provide more processing flexibility and better scalability than planetary mixers. In research, lab-scale extruders are applied in investigations that are relevant for upscaling to production on topics like all solid-state batteries (ASSBs), and solvent-free electrode processing.

To learn more about extrusion or geometry for battery applications, visit our advanced battery technology website for application notes, videos, and webinars.

Image Credit: Thermo Fisher Scientific

Annika Völp, Dr.-Ing is an Application Specialist with Thermo Fisher Scientific focusing on the extrusion of polymers and twin-screw compounding of battery materials. Annika received her Dr. -Ing from the Institute for Mechanical Engineering and Mechanics, Karlsruhe Institute of Technology (KIT), Karlsruhe, Germany. During her Ph.D. studies, she investigated the structure and rheology of foams. Annika also has a degree in Bioengineering from KIT.

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific – Materials & Structural Analysis.

For more information on this source, please visit Thermo Fisher Scientific – Materials & Structural Analysis.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.

Please use one of the following formats to cite this article in your essay, paper or report:

Thermo Fisher Scientific – Materials & Structural Analysis. (2023, August 17). Twin-Screw Extrusion in Battery Manufacturing and Research. AZoM. Retrieved on September 26, 2023 from https://www.azom.com/article.aspx?ArticleID=22658.

Thermo Fisher Scientific – Materials & Structural Analysis. "Twin-Screw Extrusion in Battery Manufacturing and Research". AZoM. 26 September 2023. <https://www.azom.com/article.aspx?ArticleID=22658>.

Thermo Fisher Scientific – Materials & Structural Analysis. "Twin-Screw Extrusion in Battery Manufacturing and Research". AZoM. https://www.azom.com/article.aspx?ArticleID=22658. (accessed September 26, 2023).

Thermo Fisher Scientific – Materials & Structural Analysis. 2023. Twin-Screw Extrusion in Battery Manufacturing and Research. AZoM, viewed 26 September 2023, https://www.azom.com/article.aspx?ArticleID=22658.

Do you have a question you'd like to ask regarding this article?

AZoM.com - An AZoNetwork Site

Single Extruder Owned and operated by AZoNetwork, © 2000-2023